0102030405

Vibro-Meter IQS452 204-452-000-221 Vibration Monitoring

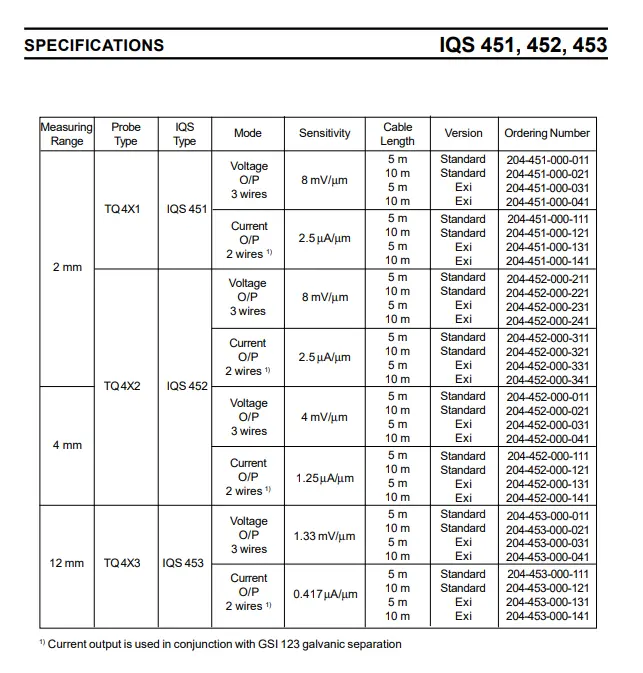

ordering informationVOGI

CHARACTERISTICS :

• For use with the TQ 400 series transducers

• Temperature compensated

• Conforms to API 670 recommendations

• Certified to CENELEC standards

• Output protected against short circuits

• Voltage or current output

Main application areas:

VOGI

Main application areas:

Energy industry

Gas turbine/steam turbine: Vibro-Meter IQS452 204-452-000-221 monitors bearing vibration and shaft displacement to prevent mechanical failure.

Wind turbine: monitors the vibration of gearbox and main shaft to optimize maintenance cycle.

Hydropower station: used for condition monitoring of hydro-generator set.

Oil and gas

Compressor/pump set: monitors the vibration of high-speed rotating equipment to avoid unplanned downtime.

Pipeline transportation system: with flow meter and pressure sensor, realizes comprehensive health monitoring.

Industrial manufacturing

Large motor/generator: real-time monitoring of vibration exceeding the standard, triggering alarm or shutdown.

Papermaking/metallurgical equipment: Vibro-Meter IQS452 204-452-000-221 protects high-load machinery (such as rolling mill, fan) from damage.

Aerospace

Aircraft engine test bench: monitor vibration parameters during R&D or maintenance.

Rail transit

Traction motor/gearbox: used for predictive maintenance of high-speed rail or subway vehicles.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$42 |

|

Southeast Asia |

$15 |

|

South Asia |

$55 |

|

South Africa |

$47 |

|

Europe and USA |

$27 |

|

Russia |

$50 |

Related supporting products:

VOGI

Vibro-Meter IQS452 204-452-000-221 usually needs to work with other hardware and software to form a complete monitoring system:

Sensor matching

Acceleration sensor: used for high-frequency vibration measurement.

Eddy current probe: monitor shaft displacement or speed.

Signal processing and transmission

Preamplifier: signal conditioning and amplification.

Data acquisition card: convert analog signals into digital signals for system analysis.

Control system integration

PLC/DCS: connect with control systems such as Siemens and ABB to achieve automated protection.

Industrial communication protocol: supports Modbus, Profibus and other protocols for easy data integration.

Software platform

VM600 monitoring software: provides real-time data analysis, trend recording and alarm management.

Third-party analysis tools: long-term data storage and advanced diagnosis.

Redundancy and safety

Dual-channel configuration: improve reliability through redundant modules.

Safety barrier: such as Pepperl+Fuchs isolation barrier.