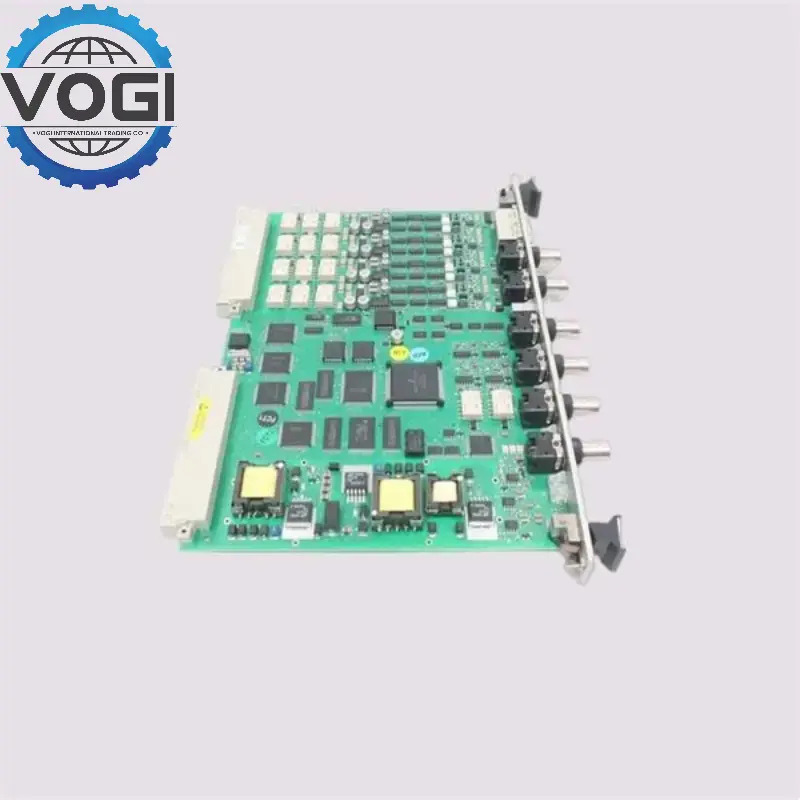

Vibro-Meter MPC4 200-510-070-113 Machinery Protection Card

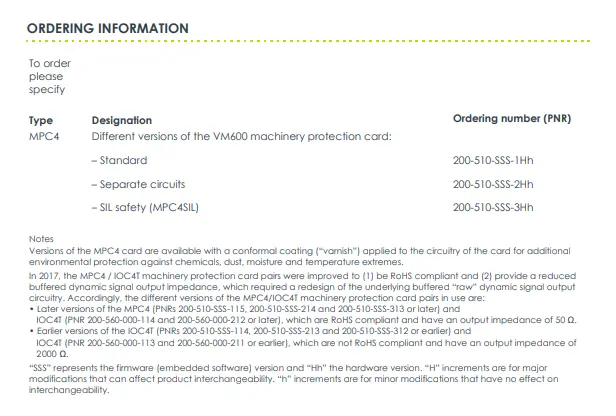

ordering informationVOGI

KEY FEATURES AND BENEFITS :

• From the Vibro-Meter® product line

• Continuously online machinery protection card

• Real-time measurement and monitoring using state-of-the-art DSP techniques

• 4 dynamic signal channels and 2 tachometer (speed) channels, all individually programmable

• Programmable broad-band and narrow-band filters

• Simultaneous amplitude and phase monitoring in order-tracking mode

• Programmable Alert, Danger and OK set points

• Adaptive Alert and Danger levels

• Front-panel BNC connectors for easy analysis of buffered “raw” sensor signals

• Front-panel LEDs indicate status and alarms

Description:

VOGI

Description:

The MPC4 machinery protection card is the central element in the VM600 series machinery protection system (MPS), from Meggitt Sensing Systems’ Vibro-Meter® product line. This very versatile card is capable of measuring and monitoring up to four dynamic signal inputs and up to two speed inputs simultaneously.

The dynamic signal inputs are fully programmable and can accept signals representing acceleration, velocity and displacement (proximity), among others.

On-board multi-channel processing allows measurement of various physical parameters, including relative and absolute vibration, Smax, eccentricity, thrust position, absolute and differential housing expansion, displacement and dynamic pressure.

Digital processing includes digital filtering, integration or differentiation (if required), rectification (RMS, mean value, true peak or true peak-to-peak), order tracking (amplitude and phase) and measurement of the transducer-target gap.

The speed (tachometer) inputs accept signals from a variety of speed sensors, including systems based on proximity probes, magnetic pulse pick-up sensors or providing TTL signals. Fractional tacho ratios are also supported.

The calibration may be expressed in metric or imperial units. Alert and Danger set points are fully

programmable, as are alarm time delay, hysteresis and latching. The Alert and Danger levels can be adapted as a function of the speed or any external information.

A digital output is available internally (on the corresponding IOC4T card) for each alarm level.

These alarm signals may be routed on a bus within the VM600 rack to drive relays on optional relay cards (such as the IRC4 and RLC16).

The processed dynamic (vibration) signals and speed signals are available at the rear of the rack (on the front panel of the IOC4T) as analog output signals.

Voltage-based (0 to 10 V) and current-based (4 to 20 mA) signals are provided.

The MPC4 performs a self-test and diagnostic routine on power-up. In addition, the card’s built-in

“OK System” continuously monitors the level of signals provided by the sensors and indicates any

problem due to a broken transmission line, faulty transducer or conditioner.

An LED indicator on the MPC4 front panel indicates whether a processing or hardware error has occurred.

Six additional LEDs (one per input channel) indicate whether the OK System has detected a fault and whether an alarm has occurred on the channel.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$35 |

|

Southeast Asia |

$15 |

|

South Asia |

$45 |

|

South Africa |

$37 |

|

Europe and USA |

$24 |

|

Russia |

$42 |

Details:

VOGI

MPC4 card

The MPC4 machinery protection card is the central element in the machinery protection system (MPS). This very versatile card is capable of measuring and monitoring up to four dynamic signal inputs and up to two speed inputs simultaneously.

The dynamic signal inputs are fully programmable and can accept signals representing acceleration, velocity and displacement (proximity), among others. On-board multichannel processing allows measurement of various physical parameters, including relative and absolute vibration, Smax, eccentricity, thrust position, absolute and differential housing expansion, displacement and dynamic pressure.

Digital processing includes digital filtering, integration or differentiation (if required), rectification (RMS, mean value, true peak or true peak-to-peak), order tracking (amplitude and phase) and measurement of the sensor-target gap.

The speed (tachometer) inputs accept signals from a variety of speed sensors, including systems based on proximity probes, magnetic pulse pickup sensors or TTL signals. Fractional tachometer ratios are also supported.

The configuration can be expressed in metric or imperial units. Alert and Danger set points are fully programmable, as are alarm time delay, hysteresis and latching. The Alert and Danger levels can also be adapted as a function of the speed or any external information.

A digital output is available internally (on the corresponding IOC4T input/output card) for each alarm level. These alarm signals can drive four local relays on the IOC4T card and/or can be routed using the rack’s Raw bus or Open Collector (OC) bus to drive relays on optional relay cards such as the RLC16 or IRC4.

The processed dynamic (vibration) signals and speed signals are available at the rear of the rack (on the front panel of the IOC4T) as analog output signals. Voltage-based (0 to 10 V) and current-based (4 to 20 mA) signals are provided.