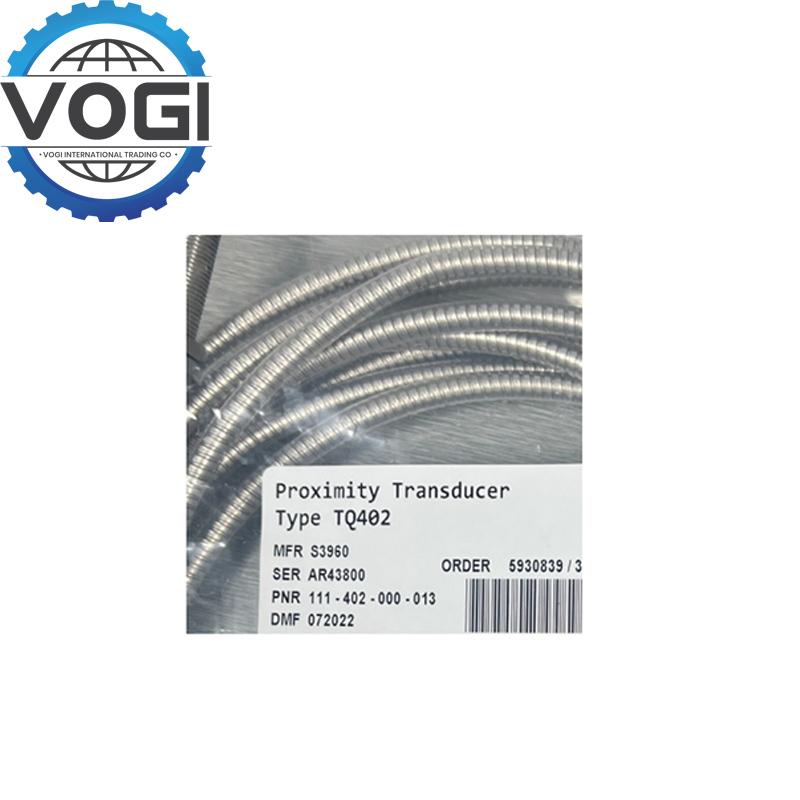

Vibro-Meter TQ402 111-402-000-012 A1-B1-C042-D000-E010-F1-G010-H10 Proximity Sensor

Technical ParametersVOGI

Part Number & Configuration

Base PN: 111-402-000-012

Suffix Breakdown:

A1: TQ402 series, eddy-current probe

B1: 0–2.5 mm nominal measuring range

C042: 42 mm probe body length

D000: Standard hardened-steel tip (no extension)

E010: Standard M6 × 0.5 mounting thread

F1: Stainless-steel probe housing (alloy 1.7225)

G010: 10 m integral coaxial cable

H10: PTFE insulation with stainless-steel braid

Measuring & Electrical

Range: 0–2.5 mm linear (best operated 0.1–2.5 mm)

Sensitivity: 4 mV/µm (voltage-mode); optional current-mode via conditioner

Frequency Response: DC to 20 kHz (–3 dB)

Output Impedance: ~500 Ω (voltage mode); ≤ 800 Ω load (current mode)

Supply: –20 to –32 V DC from conditioner (≈ 13 mA draw)

Mechanical & Environmental

Probe Body: 42 mm length × 12 mm Ø, stainless-steel housing

Tip: Hardened-steel, flush-mounted, no extension

Cable: 10 m PTFE-insulated coax, stainless-steel braid

Temperature: –25 °C to +140 °C operating; –40 °C to +150 °C storage

Shock: 50 g, 2 ms (tip)

Vibration: ≤ 25 g peak, 5 Hz–5 kHz

Pressure: Up to 100 bar at probe face

Ingress: IP 65 at tip; IP 40 at cable junction

Certifications

ATEX Zone 1 (Ex ia IIC T6)

CSA Class I, Div 1, Groups A B C D

IEC 60529 / CE / CENELEC

Key Features

VOGI

Precise Noncontact Measurement

Linear, high-resolution displacement over 0–2.5 mm with ≤ 1 % nonlinearity when paired with a matching conditioner.

Robust Industrial Design

Stainless-steel housing and hardened tip resist shock, vibration, pressure (100 bar), and temperatures up to +140 °C. PTFE-insulated, steel-braided cable withstands chemicals and abrasion.

Long-Reach Cabling

Integral 10 m low-capacitance cable preserves full bandwidth and simplifies routing in large machinery rooms.

Explosion-Proof & Intrinsically Safe Ready

ATEX and CSA approvals allow installation in hazardous zones; pairs with remote conditioners for intrinsic-safety.

Standard Mounting & Compatibility

M6 × 0.5 thread fits ν-blocks or bearing brackets; fully compatible with IQS450/IQS452 conditioners and VM600 protection/monitoring cards.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$42 |

|

Southeast Asia |

$15 |

|

South Asia |

$55 |

|

South Africa |

$47 |

|

Europe and USA |

$27 |

|

Russia |

$50 |

Applications

VOGI

Hydro-Turbine Runner Deflection & Vibration

Mounted on runner wall, capturing both slow thermal bow (DC) and high-frequency resonance. Data drives preventive maintenance on wicket gates and bearing seals.

Submerged Pump Shaft Clearance

Installed through a sealed port into a submerged pump. 10 m cable to topside VM600 cabinet enables continuous eccentricity monitoring in wet, high-pressure environments.