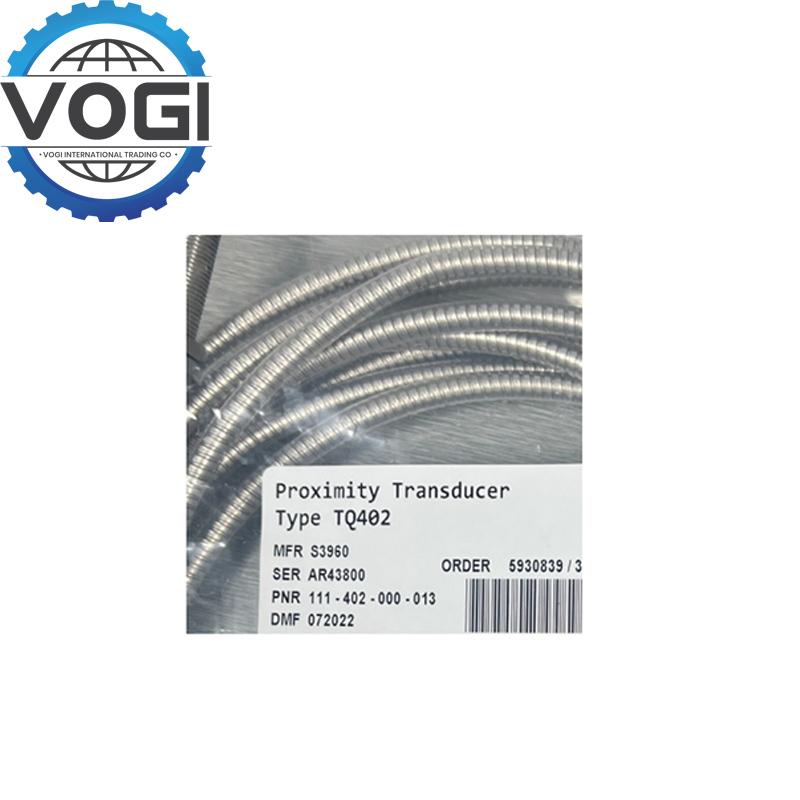

Vibro-Meter TQ402 111-402-000-013 A1-B1-C040-D000-E010-F0-G000-H05 Proximity Sensor

Technical ParametersVOGI

Measuring Range & Sensitivity

0–2.5 mm linear span

4 mV/µm (voltage mode) or 1.25 µA/µm (current mode)

Frequency & Linearity

DC to 20 kHz (–3 dB)

≤ ± 1 % non-linearity over full span (with matched conditioner)

≤ 5 % interchangeability between identical probes

Electrical & Cable

Powered by –20 V to –32 V DC (≈ 13 mA) from conditioner

Output impedance ~ 500 Ω (voltage) / drive ≤ 800 Ω (current)

No integral cable; accepts up to 5 m user-supplied PTFE-insulated, shielded coax (per H05 spec)

Mechanical & Environmental

Body length: 40 mm; diameter: 12 mm; aluminum housing

Hardened-steel, flush-mount tip

Mounting thread: M6 × 0.5

Operating: –25 °C to +140 °C; Storage: –40 °C to +150 °C

Shock: 50 g, 2 ms; Vibration: ≤ 25 g, 5 Hz–5 kHz

Pressure: up to 100 bar at probe face

Ingress: IP 65 at tip; IP 40 at cable entry

Certifications

ATEX Zone 1 (Ex ia IIC T6)

CSA Class I Div 1 Groups A B C D

IEC 60529 / CE / CENELEC

Key Features

VOGI

Custom Cable Flexibility

Field-fit up to 5 m of PTFE-insulated, shielded coax; choose connectors and routing for each installation.

Lightweight, Durable Housing

Aluminum body reduces mass on sensitive shafts; withstands industrial shock, vibration, and pressure.

Wideband, High-Resolution Sensing

Captures slow centerline shifts and high-frequency vibration (DC–20 kHz) without external filters; ≤ 1 µm resolution.

Rugged Environmental Tolerance

Rated for extreme temperatures, high pressure, and corrosive or splash-zone conditions.

Hazard-Zone Ready

Intrinsically safe approvals when paired with approved conditioners, enabling direct installation in explosive atmospheres

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$42 |

|

Southeast Asia |

$15 |

|

South Asia |

$55 |

|

South Africa |

$47 |

|

Europe and USA |

$27 |

|

Russia |

$50 |

Applications

VOGI

Customized Shaft-Monitoring Retrofitting

Use the bare-cable variant to retrofit probes in long machinery rooms—cable length and connectors tailored on-site for pumps, compressors, or turbines.

High-Temperature Turbine Bearings

Aluminum probe minimizes added mass; mounted on steam-turbine journal bearings, feeding conditioners that drive protection cards to trip on excessive eccentricity.

Process Pump Clearance & Vibration

Probe installed through a high-pressure pump housing; user-run cable to explosion-proof conditioner cabinet; monitors shaft eccentricity and vibration to prevent cavitation and seal failure.