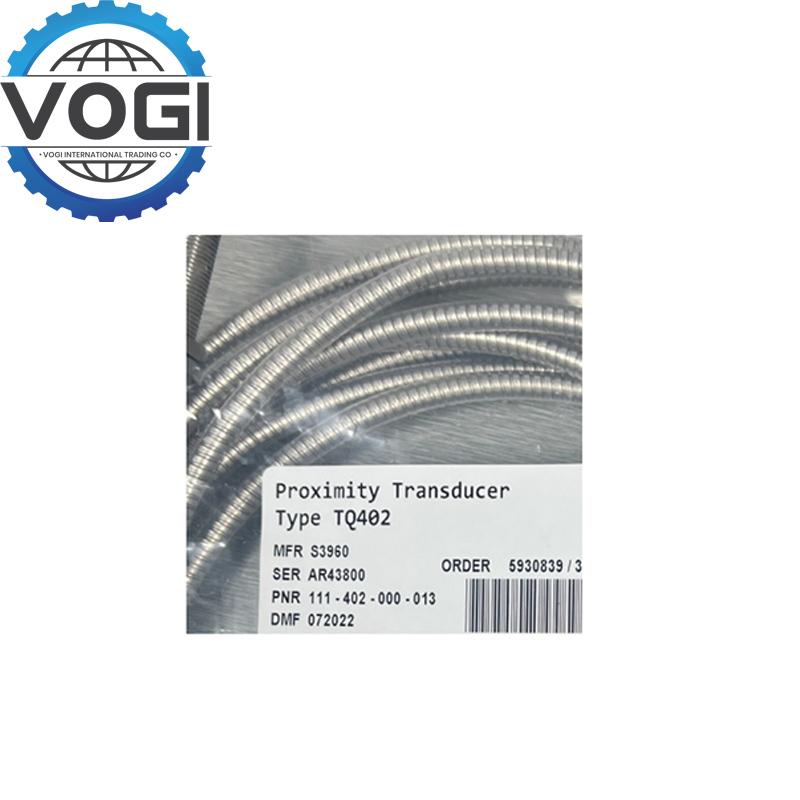

Vibro-Meter TQ402 Proximity Sensor

Technical ParametersVOGI

Model & Series: TQ402 (111-402-000-xxx variants)

Measuring Range: 0 – 2.5 mm (linear over full span)

Sensitivity: 4 mV/µm (voltage mode) or 1.25 µA/µm (current mode)

Frequency Response: DC – 20 kHz (–3 dB)

Linearity: ≤ ± 1 % full-scale (with matched conditioner)

Interchangeability: ≤ 5 % variation between probes of same type

Supply: –20 V to –32 V DC via conditioner (≈ 13 mA draw)

Output Impedance: ≈ 500 Ω (voltage) / ≤ 800 Ω load (current)

Key Features

VOGI

High-Precision Non-Contact Sensing

Linear displacement and vibration capture over a wide bandwidth without moving parts.

Robust Construction

Withstands extreme shock, vibration, temperature, pressure, and corrosive environments.

Versatile Mounting & Cabling

Multiple body lengths, thread options, and cable configurations for flexible installations.

Intrinsic-Safety & Explosion-Proof Ready

ATEX Zone 1 and CSA Div 1 approvals (with appropriate conditioners) for hazardous areas.

Temperature Compensation

Built-in circuitry maintains stable sensitivity across the full operating range.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$42 |

|

Southeast Asia |

$15 |

|

South Asia |

$55 |

|

South Africa |

$47 |

|

Europe and USA |

$27 |

|

Russia |

$50 |

Applications

VOGI

Steam-Turbine Journal Bearing Monitoring

Tracks shaft centerline at high speeds; paired with IQS450/452 and VM600 MPC4 to detect misalignment or bearing wear before damaging rubs occur.

Compressor Air-Gap Surveillance

Measures impeller clearance in gas-compression trains; rapid detection of gap reduction prevents blade tip rubbing and mechanical failure.

Hydroelectric Runner Position & Vibration

Monitors thermal bow and high-frequency resonances in turbine runners; enables preventive maintenance on wicket gates and seals.