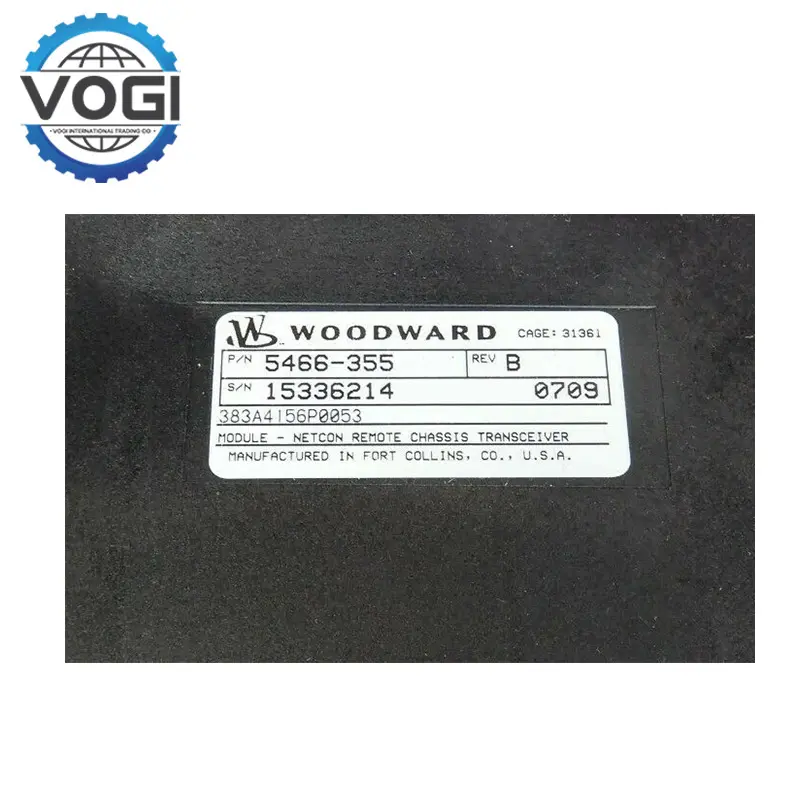

Woodward 5466-355 Netcon Remote Chassis Xcvr

Key SpecificationsVOGI

Power Supply: 24 V DC (typical range: 18–32 V DC).

Operating Temperature: -40°C to +85°C (-40°F to +185°F).

Accuracy: ±0.5% full scale (typical for actuator control modules).

Communication: Optional CANbus, Modbus, or Woodward proprietary protocols (varies by configuration).

Protection: IP20/IP65 (depends on housing), vibration/shock resistant.

Key FeaturesVOGI

High-Speed Communication and Integration: Woodward 5466-355 facilitates seamless data exchange between the Main Chassis and Remote I/O Chassis via a VME bus, ensuring real-time communication for industrial automation systems; Equipped with 100-pin metal shell Micro-D connectors and high-speed differential line drivers to support stable and reliable signal transmission over long distances.

Robust Connectivity and Expansion: Designed to connect remote I/O components to the main control system, enabling scalable expansion of industrial networks. It requires installation in Slot 1 of the Remote I/O chassis and supports cascading with expansion units using 10-foot (3 m) shielded cables; Requires termination resistors for the last expansion chassis in the chain to maintain signal integrity.

Environmental Resilience:Woodward 5466-355 functions reliably in harsh industrial environments with a temperature range of -40°C to +70°C, ensuring adaptability to extreme conditions; Supports operation in environments with ≤95% relative humidity.

Compatibility and Application Scope: Optimized for integration with Woodward’s CPU 68040 systems, supporting industrial automation tasks such as turbine control, power generation, and distributed control systems (DCS); Enables redundant configurations to enhance system reliability in critical applications.

Freight Estimation(Part Of The Area)VOGI

|

Destination |

Freight |

|

Middle East |

$43 |

|

Southeast Asia |

$16 |

|

South Asia |

$68 |

|

South Africa |

$46 |

|

Europe and USA |

$28 |

|

Russia |

$52 |

APPLICATIONVOGI

Industrial Automation and Process Control: Woodward 5466-355 acts as the central processing unit (CPU) in Micronet systems, coordinating communication between field devices and supervisory control layers. It manages analog and digital I/O signals to regulate processes like conveyor belt speed or robotic arm positioning; Processes real-time data from sensors (e.g., temperature, pressure) and adjusts control outputs via Modbus RTU or CANopen protocols, ensuring seamless integration with PLCs and SCADA systems.

Oil and Gas Infrastructure:Enables remote monitoring of flow rates, pressure sensors, and safety valves in offshore platforms or remote drilling sites. The module’s -40°C to +70°C operating range ensures functionality in harsh environments; Coordinates with Woodward’s digital governors to optimize energy efficiency and prevent equipment fatigue in midstream operations.

Heavy Machinery and Manufacturing: Woodward 5466-355 manages spindle speed and tool positioning in CNC machines via analog outputs, ensuring precision in metalworking or additive manufacturing; Synchronizes robotic arms and conveyor systems using digital I/O signals, reducing downtime and enhancing throughput.

Process Automation and Smart Factories: Woodward 5466-355 supports Ethernet-APL for long-distance, low-power communication in process automation (e.g., chemical plants). This allows integration of advanced field devices with enhanced edge processing capabilities; Monitors output voltage, current, and faults (via FAULT LED), enabling predictive maintenance and minimizing unplanned downtime.