0102030405

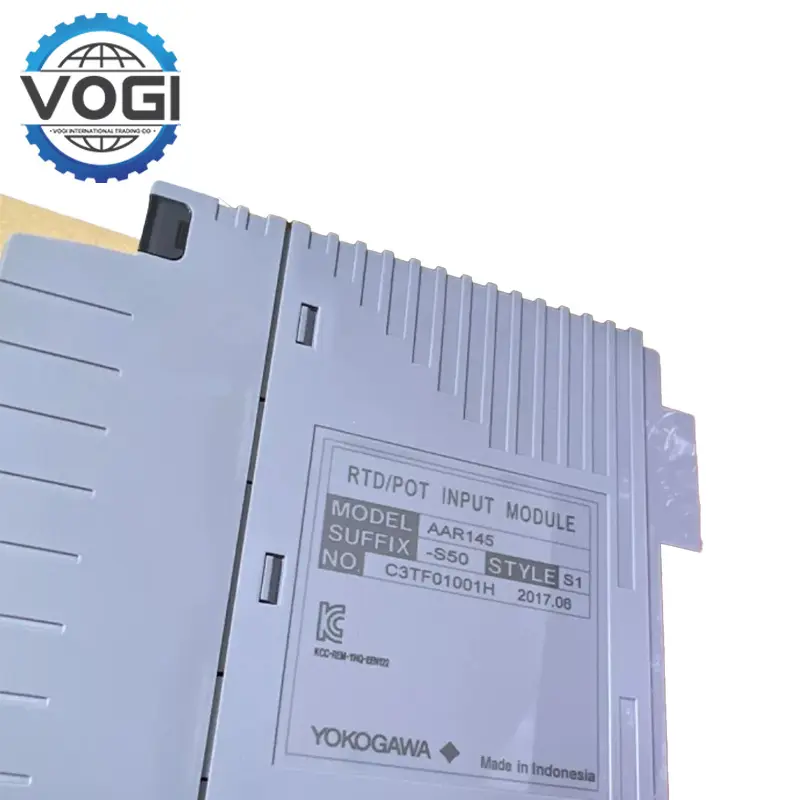

Yokogawa AAR145-S50 RTD/POT Input Module

Key SpecificationsVogi

Allowable Input Voltage: ±5 V.

Input Resistance: 1 MΩ when powered on and off.

Accuracy: ±150 mΩ for RTD and ±0.2%/FS for POT.

Allowable Total Resistance of Signal Source plus Wiring: 150 Ω.

Measurement Current: 1 mA for RTD.

Maximum Current Consumption: 350 mA (5 V DC).

Temperature Drift: ±0.3 Ω/10 °C for RTD and ±0.4%/10 °C for POT.

Key FeaturesVogi

Supports multi-protocol communication and system integration: Yokogawa AAR145-S50 integrates RS-485 and Ethernet (TCP/IP) interfaces, natively supports Modbus RTU/TCP protocols, and can be directly connected to DCS, SCADA, or host computer systems. With the expansion module can be compatible with Profibus DP, HART, Foundation Fieldbus and other protocols, seamless data interaction with PLC, smart instruments and third party equipment. In oil and gas pipeline monitoring, the positioning data of the smart valve is read through the HART protocol and uploaded to the central control room.

Applicable for real-time alarm and safety control: With built-in 8 programmable alarm channels for threshold triggering, delayed alarm (0 ~ 60 seconds adjustable) and multi-level linkage control. For example, in a boiler system, when an over-temperature condition occurs, the alarm will automatically turn off the fuel valve and send a text message to the operation and maintenance personnel. By time/event classifiable, built-in 8GB flash read/write storage alarm record can be exported for convenient accident tracing and compliance auditing.

Remote management and data storage: Reduction of maintenance costs is done by the ability to perform the configuration and firmware upgrades remotely using Yokogawa VPServer software, which allows remote download of data; it also supports cyclic storing mode (up to 30 days of historical data) with data export to CSV or Excel format for energy efficiency or process optimization. Thus, in a water treatment plant, long-term recording of pH and turbidity data could aid in developing an approach for delivering the chemical agents.

Freight Estimation(Part Of The Area)Vogi

|

Destination |

Freight |

|

Middle East |

$34 |

|

Southeast Asia |

$15 |

|

South Asia |

$44 |

|

South Africa |

$36 |

|

Europe and USA |

$24 |

|

Russia |

$41 |

ApplicationVogi

Semiconductor manufacturing: Yokogawa AAR145-S50 can be used to gather data on vacuum chamber pressure and wafer temperature in the manufacturing process, and improve yield by reducing process fluctuations through high-precision AD conversion; it can also be used to monitor gas flow in etching machines to help further improve yield.

Motor production line: Collect data on soldering machine operation parameters; synchronize with MES system via RS485 for data-sharing; maintain equipment for reliability; predict soldering machine failure.

Subway: Track wear and corrosion on rails and conductors with vibration sensors that send signals to monitoring center using 4-20mA and raising crack or settlement risk warnings.

Intelligent Building: collects temperature and humidity, CO₂ concentration of air conditioning system, and connects fresh air unit to adjust air quality; Data Center microenvironment cabinet monitoring, to prevent overheating and downtime.

Tunnels and bridges: Yokogawa AAR145-S50 deploy vibration sensors to monitor structural health, transmit 4-20mA signals to the monitoring center, and warn of cracks or settlement risks.

Ship and offshore platform: Integrated salt spray protection coating, long-term operation in humid sea conditions; monitoring ballast tank liquid level and main engine oil temperature to ensure navigation safety.